Product Description:

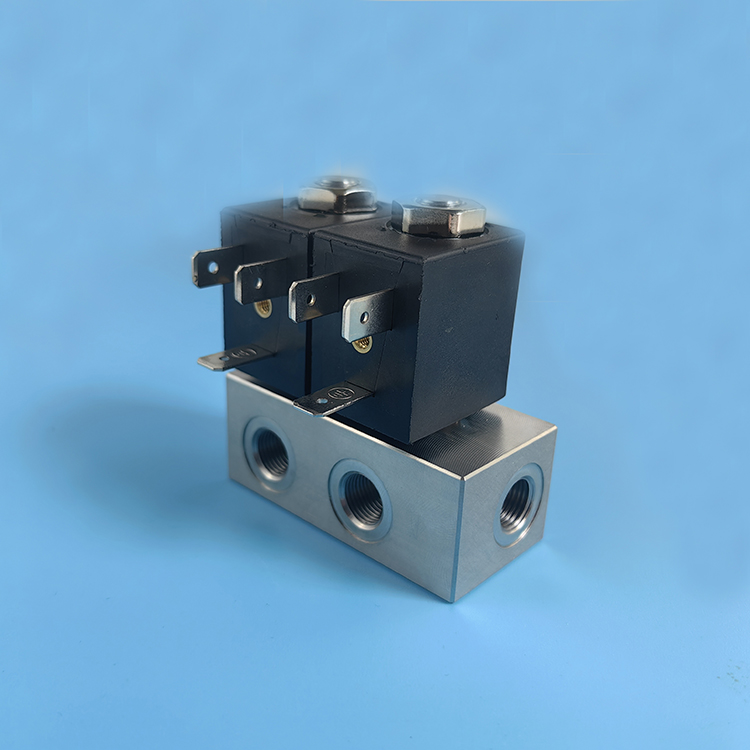

Flywire coil, micro valve group two-way solenoid valve switching 1 in 5 out 5 in 1 out, integrated valve to multiple in multiple out, stainless steel body.Pin flying wire coil, micro valve group with two-way solenoid valve switching 1 in 5 out 5 in 5 out 1 in 1 out, integrated valve with multiple in and multiple out, stainless steel valve body.

Interface: G1/8

Voltage: DC24V Flywire or Pin

Medium pressure: Bidirectional pressure resistance 0-5 bar

Medium pressure: 0-6bar

Product features:

Small structure, high precision, fast response, corrosion-resistant gas or liquid, etc.

Sample data:

Please contact online customer service.

The combination of two solenoid valves can be applied to multiple industries, and the following are some common industry applications:

1. Energy industry:

-Gas transmission and control: In the transmission system of natural gas, liquefied gas and other gases, dual solenoid valves can be used to ensure the safe supply and cut-off of gas. For example, at key nodes such as gas distribution stations and pressure regulating stations in urban gas pipelines, dual solenoid valves can quickly cut off gas supply in case of abnormal situations, preventing leaks and accidents.

-Thermal system: In centralized heating, industrial steam and other thermal systems, dual solenoid valves can be used to control the flow and on/off of steam. For example, in the steam distribution system of a thermal power station, dual solenoid valves can accurately control the supply of steam according to user needs, improving energy utilization efficiency.

2. Chemical industry:

-Fluid transportation and control: The chemical production process involves the transportation and control of a large amount of liquid and gas materials, and dual solenoid valves can accurately regulate and cut off these fluids. For example, in the feed and discharge pipelines of a chemical reactor, dual solenoid valves can ensure accurate supply of materials and timely discharge of reaction products, ensuring the stability and safety of the production process.

-Hazardous chemical handling: For some hazardous chemicals such as strong acids, strong alkalis, toxic gases, etc., the redundant design of dual solenoid valves can improve the safety of the system. During the storage, transportation, and handling of hazardous chemicals, dual solenoid valves can serve as dual safety measures to prevent the leakage of hazardous chemicals and the occurrence of accidents.

3. Mechanical manufacturing industry:

-Machine tool equipment: In the hydraulic and pneumatic systems of machine tools, dual solenoid valves can be used to control the movement of the worktable, tool feed, and other actions. For example, in the hydraulic chuck system of CNC machine tools, dual solenoid valves can ensure accurate clamping and releasing actions of the chuck, improving machining accuracy and production efficiency.

-Automated production line: On an automated production line, dual solenoid valves can be used to control the actions of various actuators, such as the extension and retraction of cylinders, the grasping and placement of robotic arms, etc. The high reliability and precise control capability of dual solenoid valves can ensure the stable operation of the production line, improve production efficiency and product quality.

4. Food and beverage industry:

-Beverage filling: In the beverage filling production line, dual solenoid valves can be used to control the filling flow and filling time of beverages. For example, in the filling process of carbonated beverages, dual solenoid valves can ensure the accurate injection of carbon dioxide gas and the filling amount of the beverage, ensuring the taste and quality of the beverage.

-Food processing: In the process of food processing, dual solenoid valves can be used to control the on/off and flow of media such as steam, water, and oil. For example, in food cooking, frying, and other processing processes, dual solenoid valves can accurately control the supply of steam and oil, ensuring the quality and safety of food processing.

5. Water treatment industry:

-Sewage treatment: In the sewage treatment system, dual solenoid valves can be used to control the flow and direction of sewage. For example, in the aeration tank, sedimentation tank and other process links of sewage treatment plants, dual solenoid valves can accurately control the mixing ratio and residence time of air and sewage according to process requirements, improving the sewage treatment effect.

-Drinking water treatment: In the drinking water treatment system, dual solenoid valves can be used to control the amount and timing of disinfectants, coagulants, and other chemicals added. For example, in the dosing process of a water plant, dual solenoid valves can ensure the accurate addition of chemicals, ensuring the quality and safety of drinking water.

6. Automotive manufacturing industry:

-Engine control system: In the fuel injection and intake systems of automobile engines, dual solenoid valves can be used to control the injection and intake of fuel, improving the combustion efficiency and power performance of the engine. For example, in the fuel injection system of gasoline engines, dual solenoid valves can accurately control the injection time and amount of fuel according to the engine's operating conditions, reducing fuel consumption and emissions.

-Braking system: In the braking system of a car, dual solenoid valves can be used to control the pressure and flow of brake fluid, achieving precise control of braking. For example, in anti lock braking systems (ABS), dual solenoid valves can accurately control the pressure of brake fluid based on the speed of the wheels and the pressure of the brake pedal, preventing wheel lock up and improving braking safety and stability.

7. Pharmaceutical industry:

-Drug production: During the drug production process, dual solenoid valves can be used to control the transportation and mixing of various drugs and solvents. For example, in the process of drug synthesis, extraction, concentration, etc., dual solenoid valves can ensure the accurate supply and mixing ratio of the drug solution, ensuring the quality and purity of the drug.

-Aseptic production: In the production process of sterile drugs, the sterile design and high reliability of dual solenoid valves can meet the requirements of aseptic production. For example, in the production process of injections, dual solenoid valves can be used to control the supply of sterile air and the filling of medication, ensuring the sterility and safety of the drugs.

Contact: peng gong

Phone: 18918462396

Tel: 021-59718851

Email: kunage@126.com

Add: Lane 819, Qinghewan Road, Qingpu Industrial Park, Qingpu District, Shanghai