product description:

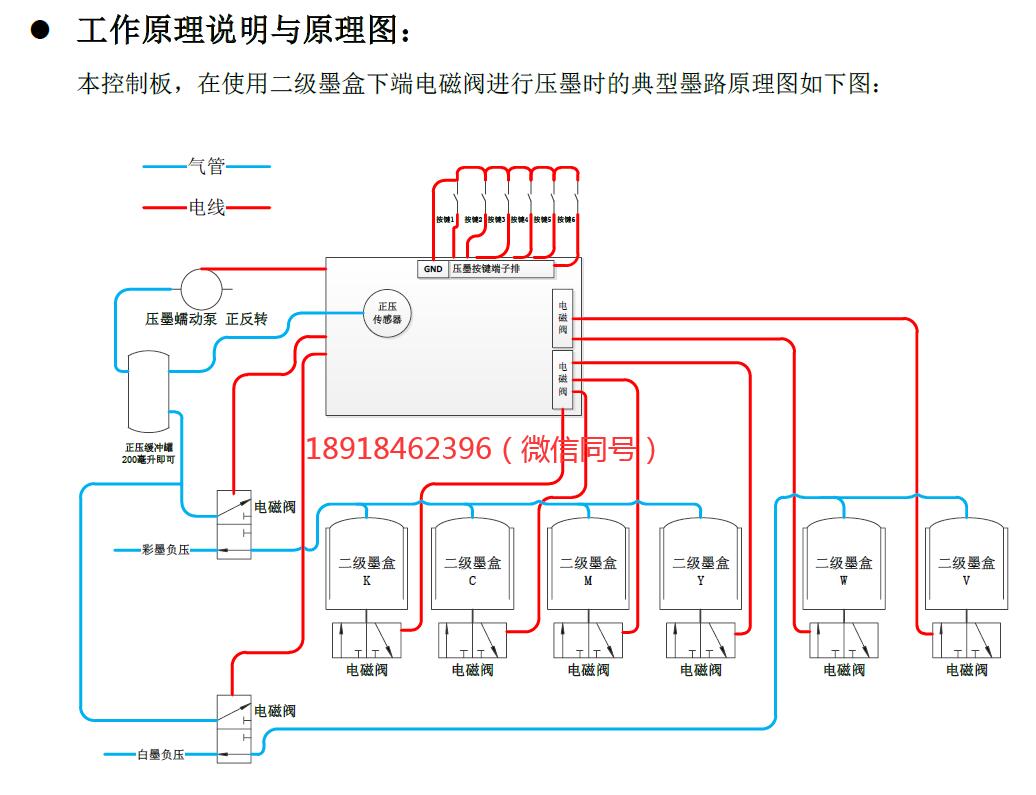

This control board is a separate control board, which mainly realizes two main functions.

The first is to realize the start-stop control of the solenoid valve at the lower end of the secondary ink cartridge, and to control the working voltage of the solenoid valve to reduce the heating of the solenoid valve, thereby reducing power consumption.

The second is to use the solenoid valve on the secondary ink cartridge to realize the function of color separation and separate ink pressure, and the pressure of the ink pressure is controllable to avoid damage to the nozzle due to excessive pressure. Avoid air pressure fluctuations.

Board and wiring instructions, see the figure below.

Wiring Instructions:

24v power supply: board power supply, 12V or 24V can be used, mainly depends on the working voltage of the solenoid valve on the secondary ink cartridge and the working voltage of the peristaltic pump.

The first to the eighth solenoid valve: There are two groups of terminals, each group is connected to 4 solenoid valves, the positive and negative poles are wired separately, and are connected to the solenoid valve at the lower end of the secondary ink cartridge. As long as the solenoid valve is connected and the card board is powered, the solenoid valve will enter the step-down output mode after 1 second after starting (for voltage setting, see the parameter setting description below), and the board card can be used normally. If you don't need color separation and pressure ink, the wiring is completed and you can use it.

The first to the eighth way of pressing the ink button: This group of terminals is used to connect the pressing ink control button when the ink needs to be pressed. There are a total of 9 interfaces. The leftmost port is the GND terminal of the power supply, and the remaining 8 are switches. Button wiring. No matter how many switch buttons are used, one end of the switch is all connected in parallel and then connected to the GND terminal of the power supply, and the other end is connected to other terminal holes. Up to 8 buttons can be connected, that is, the board supports up to 8 channels of individual ink pressing.

Ink-pressing peristaltic pump: This terminal is used to connect the peristaltic pump that generates the ink-pressing air pressure. Since the peristalsis is positive and negative, it can generate positive pressure and negative pressure. Therefore, when the board controls the ink-pressing, the negative pressure is changed to positive pressure first. Press the ink, change the negative pressure after the ink is pressed, and then switch to the negative pressure of the ink path to achieve smooth switching.

Two-way pressure ink switching solenoid valve: Since the normal ink circuit is working, there is negative pressure in the secondary ink cartridge, while the pressure ink uses positive pressure, and the positive pressure and negative pressure are generated by two different control units, so it is necessary to To switch, use a two-position three-way solenoid valve (air valve) to switch, these two terminals are connected to the switching solenoid valve.

Ink pressure positive pressure sensor: When pressing ink, it is necessary to control the ink pressure pressure, and the feedback of the ink pressure pressure is the responsibility of the sensor. When the pressure reaches or exceeds the set pressure, the pumping work of the ink pressure peristaltic pump will be suspended. In order to protect the nozzle and avoid damage to the nozzle due to excessive pressure.

Sample data:

Please contact online customer service.

product description:

product description:

This control board is a separate control board, which mainly realizes two main functions.

The first is to realize the start-stop control of the solenoid valve at the lower end of the secondary ink cartridge, and to control the working voltage of the solenoid valve to reduce the heating of the solenoid valve, thereby reducing power consumption.

The second is to use the solenoid valve on the secondary ink cartridge to realize the function of color separation and separate ink pressure, and the pressure of the ink pressure is controllable to avoid damage to the nozzle due to excessive pressure. Avoid air pressure fluctuations.

Board and wiring instructions, see the figure below.

Wiring Instructions:

24v power supply: board power supply, 12V or 24V can be used, mainly depends on the working voltage of the solenoid valve on the secondary ink cartridge and the working voltage of the peristaltic pump.

The first to the eighth solenoid valve: There are two groups of terminals, each group is connected to 4 solenoid valves, the positive and negative poles are wired separately, and are connected to the solenoid valve at the lower end of the secondary ink cartridge. As long as the solenoid valve is connected and the card board is powered, the solenoid valve will enter the step-down output mode after 1 second after starting (for voltage setting, see the parameter setting description below), and the board card can be used normally. If you don't need color separation and pressure ink, the wiring is completed and you can use it.

The first to the eighth way of pressing the ink button: This group of terminals is used to connect the pressing ink control button when the ink needs to be pressed. There are a total of 9 interfaces. The leftmost port is the GND terminal of the power supply, and the remaining 8 are switches. Button wiring. No matter how many switch buttons are used, one end of the switch is all connected in parallel and then connected to the GND terminal of the power supply, and the other end is connected to other terminal holes. Up to 8 buttons can be connected, that is, the board supports up to 8 channels of individual ink pressing.

Ink-pressing peristaltic pump: This terminal is used to connect the peristaltic pump that generates the ink-pressing air pressure. Since the peristalsis is positive and negative, it can generate positive pressure and negative pressure. Therefore, when the board controls the ink-pressing, the negative pressure is changed to positive pressure first. Press the ink, change the negative pressure after the ink is pressed, and then switch to the negative pressure of the ink path to achieve smooth switching.

Two-way pressure ink switching solenoid valve: Since the normal ink circuit is working, there is negative pressure in the secondary ink cartridge, while the pressure ink uses positive pressure, and the positive pressure and negative pressure are generated by two different control units, so it is necessary to To switch, use a two-position three-way solenoid valve (air valve) to switch, these two terminals are connected to the switching solenoid valve.

Ink pressure positive pressure sensor: When pressing ink, it is necessary to control the ink pressure pressure, and the feedback of the ink pressure pressure is the responsibility of the sensor. When the pressure reaches or exceeds the set pressure, the pumping work of the ink pressure peristaltic pump will be suspended. In order to protect the nozzle and avoid damage to the nozzle due to excessive pressure.

Sample data:

Please contact online customer service.

Contact: peng gong

Phone: 18918462396

Tel: 021-59718851

Email: kunage@126.com

Add: Lane 819, Qinghewan Road, Qingpu Industrial Park, Qingpu District, Shanghai