Body material: ductile iron, cast steel, 304, 316, 316L

Valve plate material: ductile iron nickel-plated, nylon plate, 304, 316, 316L, 1.4529, 2507

Valve seat material: EPDM, NBR, PTFE, etc.

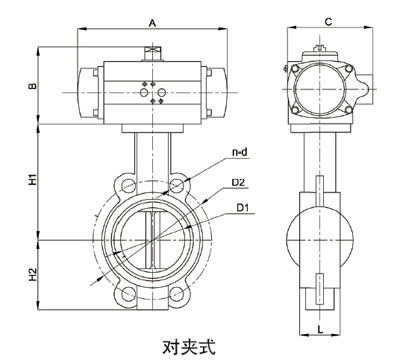

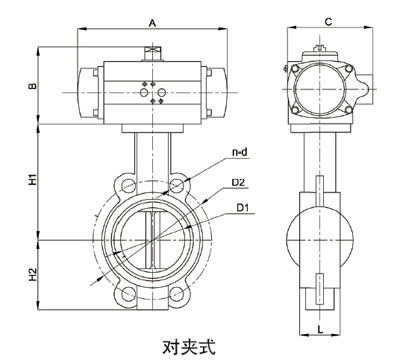

Connection method: LT wafer type

Flange standards: GB, ANSI, JIS, DIN

Pressure rating: PN10, PN16

Pneumatic actuator: double-acting, single-acting normally closed, single-acting normally open

Pneumatic accessories: solenoid valve, air

filter pressure reducing valve, electric

positioner, hand wheel, etc.

description

LT lug type pneumatic butterfly valve product overview and use

The LT lug type pneumatic butterfly valve is composed of a pneumatic actuator and a centerline butterfly valve. The pneumatic butterfly valve is equipped with a stroke limit switch, a solenoid valve, a triple piece and a 0.4-0.7MPa air source to achieve switch operation, and sends out two pairs of passive contact signal instructions The opening and closing of the valve. Matching with electric

positioner, input 4-20mADC signal and 0.4-0.7MPa air source to realize intelligent control, realize the adjustment of pressure, flow, temperature, liquid level and other para

meters. It is powered by compressed air, and the valve stem drives the valve core to rotate 90°C in the valve body, which can achieve a fully open-fully closed action. The product is divided into metal seal and soft seal according to its sealing performance. It can be widely used in industrial automatic control systems such as petroleum, chemical, offshore, and drilling platforms for remote centralized control or local control.

Features and standards

The high platform design conforms to the ISO5211 standard, and can be directly connected to the ISO5211 standard actuator. Good interchangeability

Technical para

meters of lug pneumatic butterfly valve

Valve body

Nominal dia

meter: DN50-DN600

Body material: ductile iron, 304, 316

Connection method: lug to clip type

Pressure rating: PN10, PN16

Structure: LT lug midline structure

Valve components

Valve plate material: ductile iron nickel-plated, nylon coating, aluminum bronze, 304, 316, 316L, 1.4529, 2507

Stem material: stainless steel 410, 304

Applicable medium: water, liquid, gas, oil, powder, steam

Design and manufacture standards

Design and manufacture: GB/T12238-2008

Connection standard: JB/T 79.1-1994 ASME B16.10

Structure length: GB/T12221-2005 ASME B16.5

Pressure test: GB/T13927-2008

Pneumatic actuators

Double action: Ventilation is on, ventilation is off, air source failure keeps the current position

Single-acting air-open type: vent open, cut air off, air source failure closed

Single-acting air-closing type: ventilation closed, air cut open, air source failure open

Optional accessories: reversing solenoid valve, limit switch, air

filter pressure reducing valve, electrical

positioner, handwheel mechanism, retaining valve, electrical parts can be explosion-proof

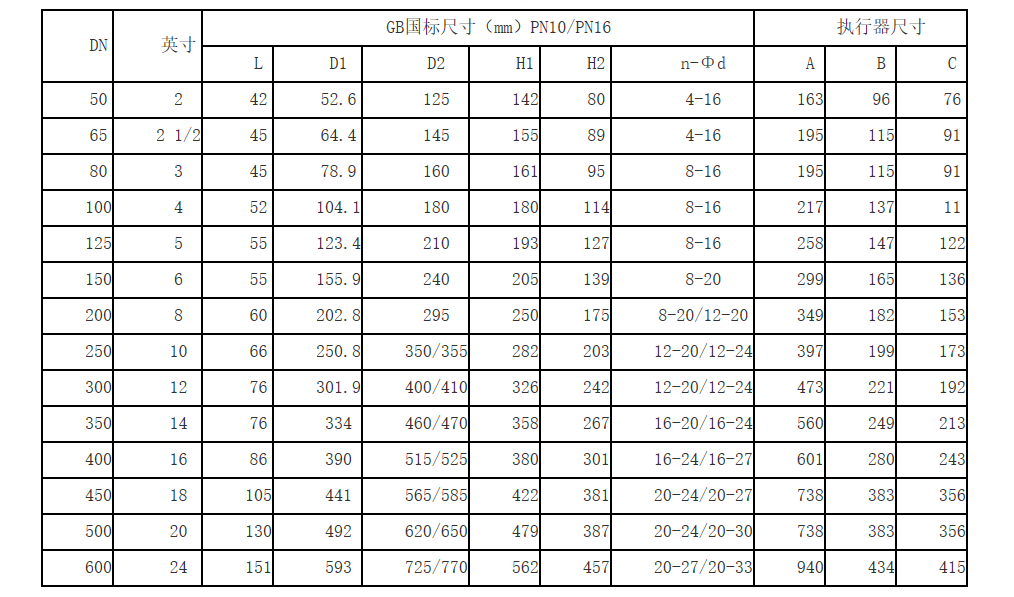

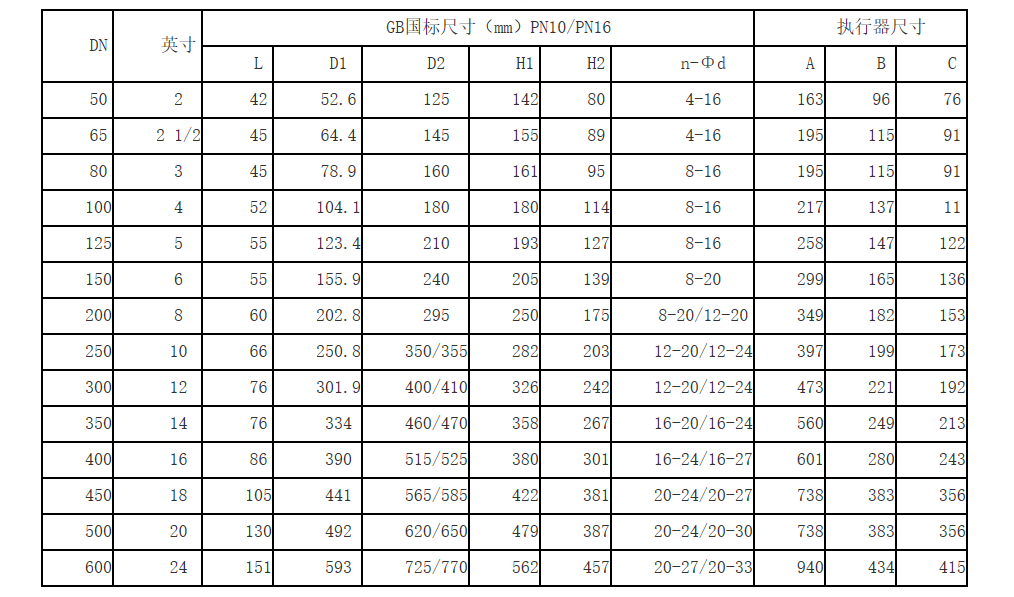

Pneumatic butterfly valve size chart

Professional manufacturing and professional services, KUNAG creates more value for you

Continuously improving the quality of services and keeping improving, "sincere service" is the eternal theme of KUNAG. Kunag strictly complies with the requirements of ISO9001-2000 quality system certification, strictly controls the quality and responsibilities to the people to ensure the healthy operation of production, sales and service. To strengthen communication with customers and to provide our customers with quality products and perfect service, we hereby make the following commitments:

Product Standards

Products are designed, manufactured, and inspected strictly in accordance with China\'s GB, HG standards, and US API standards. The hardness of the sealing surface meets the national requirements and the width exceeds the national standard.

pre-sale service

Product introduction, technical communication, non-standard product design, troubleshooting.

Sale service

Trustworthy contracts, guarantee timely delivery, and keep in touch with customers at any time.

For special or complex products, our factory arranges technicians to train and guide users on product use, troubleshooting, tuning and maintenance.

After sales service

The warranty period of Weitong products is 12 months from the factory, and the "three guarantees" service (return, replacement, repair) is implemented.

During the use of our products, our factory regularly organizes technical and inspection personnel to visit and solicit user feedback on product quality, use conditions, and improvement opinions in order to further improve product quality.

Quickly respond to customer complaints about product quality problems, and after-sales service personnel rushed to the scene within 24-36 hours (48 hours outside the province).

For after-sales service, users are required to fill in the quality feedback form after the service and make appraisal opinions, while improving Guardian\'s service quality.