Solenoid valve seal and flow detection calculation

Solenoid Valve Sealing Overview and Flow Detection Calculation

A: Overview of seal materials commonly used in fluid solenoid valves

In industrial automation products, electromagnetic valve sealing materials should be conservatively selected for use in different applications, static and dynamic situations, and relevant data are for reference.

1: Nitrile rubber (NBR)

Mainly used for static sealing of solenoid valves such as O-rings, moving iron core seals and diaphragms of solenoid valves, diaphragms according to the size of the flow path, and some valves have built-in metal parts to seal the package to enhance the life span, such as SLP series electromagnetic Valves, some using metal plate, but also increase the life of the diaphragm, such as ZS series solenoid valve. Nitrile rubber is generally used in most gases, water, light oil and other media, medium temperature -18 °C ~ 80 °C;

2: EPDM rubber (EPDM)

Mainly used for NBR sealing medium and above temperature range, food grade solenoid valve (NSF certified solenoid valve, generally use EPDM sealing material that meets standard), solenoid valve in low pressure steam pipeline, etc. It is also suitable for large Most of the gas, water, etc., therefore, such as the pilot-type SLP and direct-acting ZS series solenoid valve are used in this seal, the medium temperature is generally -20 °C ~ 139 °C can be used.

3: Viton (VITON)

Mainly used in NBR EPDM can not be used in the medium, can be used for more gases, water, gasoline, solvents, VITON has better corrosion resistance than NBR EPDM, but the price is higher than the above sealing material. In piston seals and O-ring seals, VITON seals are often used, such as the SLA solenoid valve series, but also suitable for diaphragm type stainless steel solenoid valves such as ZS, SLP, etc., but adapt to different media conditions, media The temperature is generally -20 °C ~ 169 °C can be used.

4: TEFLON

It can be applied to almost all fluids, but because of its hard and cold flow characteristics, when it is used as a dynamic seal, it is particularly prone to leaks when working under gaseous media. The price is relatively high, and the seal is good under high temperature and high pressure. General high pressure and high temperature solenoid valves such as SMG, SLG, SLA and other solenoid valve series are widely used; medium temperature is generally -180 °C ~ 200 °C can be used.

5: The solenoid valve will have more sealing materials under various working conditions such as medium, pressure, temperature, flow, etc., such as PP, PEEK, and even precious stone materials for sealing.

II: Flow Detection and Calculation of Fluid Solenoid Valves

When the solenoid valve needs to do a type test, measure the flow rate and tell the user the flow coefficient: CV value. In the test system of the Sanlixin industrial fluid solenoid valve, a flow meter measures the solenoid valve. Generally, water can be used as a medium. 1.0 3.0 5.0 kgf/cm2 Working pressure (difference), measure the flow of this valve, then compile the flow meter, the flow of the measured solenoid valve, calculate the CV value, according to the CV value can be calculated for all in accordance with the rated working pressure Flow parameters.

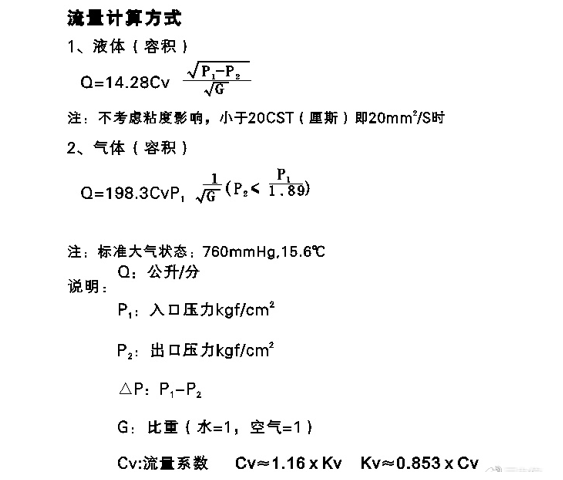

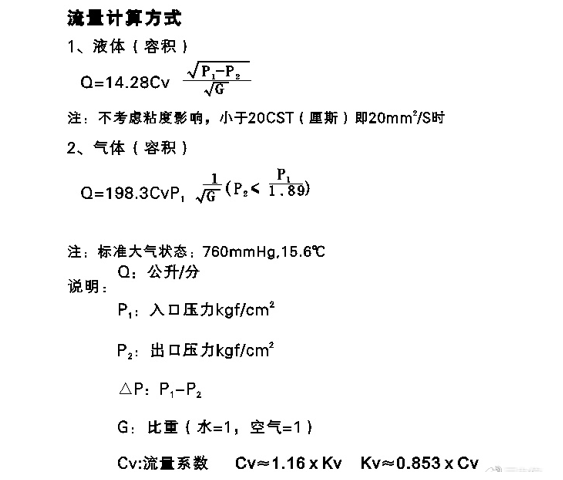

The specific calculation is as follows: